The global bleached kraft pulp market size is projected to grow at a CAGR of 5% over the forecast period of 2024-2032. This growth is indicative of the increasing demand for bleached kraft pulp across various industries, including packaging, tissue, and specialty paper. As environmental concerns drive the shift towards sustainable materials, bleached kraft pulp is becoming a critical component in paper manufacturing due to its strength, durability, and versatility. This blog post will delve into the market’s segmentation, regional analysis, dynamics, and competitive landscape to provide a comprehensive overview of the trends shaping the future of the bleached kraft pulp market.

Market Segmentation

By Process

The global bleached kraft pulp market can be segmented by the process used in its production, primarily into mechanical and chemical processes.

- Mechanical Process: The mechanical process, while less common, plays a significant role in the market due to its cost-effectiveness and lower environmental impact. It involves the physical grinding of wood into pulp without the use of chemicals. The mechanical process is often preferred for certain types of paper products where brightness and strength are not the primary requirements.

- Chemical Process: The chemical process dominates the market, accounting for the majority of bleached kraft pulp production. This method involves treating wood chips with chemicals, such as sodium hydroxide and sodium sulfide, to break down lignin and release cellulose fibers. The chemical process yields pulp that is stronger and more suitable for high-quality paper products, such as packaging and tissue paper.

- Others: Other processes, including semi-chemical methods, combine aspects of both mechanical and chemical processes. These hybrid methods are employed in niche applications where specific characteristics of the pulp are required.

By Product

The market is also segmented by the type of bleached kraft pulp produced:

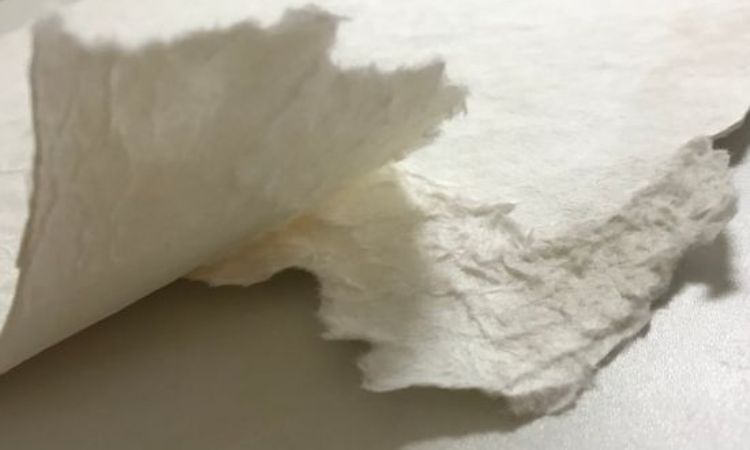

- Bleached Hardwood Kraft Pulp: Derived from deciduous trees like birch and eucalyptus, bleached hardwood kraft pulp is favored for its short fibers, which contribute to the smoothness and printability of paper. It is widely used in the production of tissue and printing papers, where a high level of brightness and softness is required.

- Bleached Softwood Kraft Pulp: Sourced from coniferous trees such as pine and spruce, bleached softwood kraft pulp is known for its long fibers, providing superior strength and durability. This type of pulp is primarily used in packaging and specialty papers, where the end products must withstand significant stress and wear.

By Application

Bleached kraft pulp is essential in various applications, each with specific market dynamics:

- Packaging Paper: As e-commerce continues to expand globally, the demand for packaging paper is on the rise. Bleached kraft pulp’s strength and durability make it an ideal material for producing high-quality, sustainable packaging solutions.

- Tissue Paper: The tissue paper segment is one of the fastest-growing applications of bleached kraft pulp. With increasing hygiene awareness and disposable income, the demand for soft, absorbent tissue products is expected to surge, driving the need for high-quality pulp.

- Graphic Paper: Though the digital age has reduced the demand for graphic paper, there remains a significant market for high-quality printing and writing paper. Bleached kraft pulp’s superior brightness and smoothness make it suitable for producing premium graphic papers.

- Newsprint Paper: The newsprint paper segment is experiencing a decline due to the shift towards digital media. However, in regions where print media remains strong, bleached kraft pulp continues to be a vital component in newsprint production.

- Specialty Papers: Specialty papers, including those used in currency, filtration, and labeling, require specific characteristics such as high strength, porosity, and purity. Bleached kraft pulp’s versatility allows it to meet these specialized needs.

- Others: Other applications include the production of paperboard, release liners, and industrial papers, where bleached kraft pulp’s unique properties are leveraged for specific end uses.

Regional Analysis

The bleached kraft pulp market is globally distributed, with significant regional variations:

- North America: North America remains a dominant player in the bleached kraft pulp market, driven by strong demand in the packaging and tissue paper sectors. The presence of well-established pulp and paper industries, coupled with advancements in sustainable practices, bolsters the market in this region.

- Europe: Europe’s market is characterized by stringent environmental regulations and a strong emphasis on sustainability. Countries like Sweden and Finland are leading producers of bleached kraft pulp, focusing on eco-friendly production methods and innovations.

- Asia-Pacific: The Asia-Pacific region is expected to witness the highest growth rate during the forecast period. Rapid industrialization, coupled with increasing demand for packaging and tissue products in countries like China and India, is driving market expansion. The region’s growing consumer base and rising environmental awareness further contribute to market growth.

- Latin America: Latin America, with its abundant forest resources, is a significant producer of bleached kraft pulp. Brazil, in particular, plays a crucial role in the global market, exporting large quantities of pulp to North America and Europe.

- Middle East & Africa: While smaller in market share, the Middle East & Africa region presents growth opportunities due to increasing urbanization and rising demand for consumer goods, which, in turn, drives the need for packaging and tissue products.

Market Dynamics

The dynamics of the bleached kraft pulp market are influenced by several factors:

- Market Drivers: Key drivers include the rising demand for sustainable and recyclable materials, growth in the e-commerce sector, and increasing consumer awareness of hygiene products.

- Market Restraints: Environmental concerns related to deforestation and water usage in pulp production pose significant challenges. Additionally, the high cost of raw materials and energy can impact profitability.

- Opportunities: Innovations in pulp production, such as the development of bio-based chemicals and improved recycling processes, present opportunities for market growth. The increasing adoption of sustainable practices by major companies also opens new avenues.

- Challenges: The market faces challenges in the form of regulatory pressures, supply chain disruptions, and competition from alternative materials like recycled paper and non-wood fibers.

Competitive Landscape

The competitive landscape of the bleached kraft pulp market is marked by the presence of several key players:

- Key Players: Companies like International Paper, Stora Enso, UPM-Kymmene, and Suzano are leading the market, focusing on expanding their production capacities and investing in sustainable practices.

- Market Strategies: Major players are adopting strategies such as mergers and acquisitions, product innovations, and collaborations to strengthen their market position. The shift towards eco-friendly products is also driving companies to develop new, sustainable pulp products.

Future Outlook (2024-2032)

The future of the bleached kraft pulp market looks promising, with projected growth driven by increasing demand for sustainable packaging and hygiene products. Emerging trends such as the development of advanced pulping technologies and the shift towards bio-based chemicals are expected to shape the market’s future. As sustainability becomes a central focus, companies that prioritize eco-friendly practices and innovations are likely to lead the market.