The specialty of Metal Stamping continues to exist within the realm of craftsmanship and innovative creativity as a representation of the flawless fusion of knowledge and ingenuity. This meticulous process entails creating intricate designs, visuals, and even text onto metal surfaces, creating creations that continually combine material devotion with stylistic beauty. Metal stamping has the power to transform raw metal into personalized works of art, with every piece catching an account of accuracy and imagination. In this essay, we go on a journey into the captivating world of stamping, exploring its undeniable significance, complex systems, and the enduring allure that results from transforming ordinary metals into works of beauty.

What Is Meant By Metal Stamping?

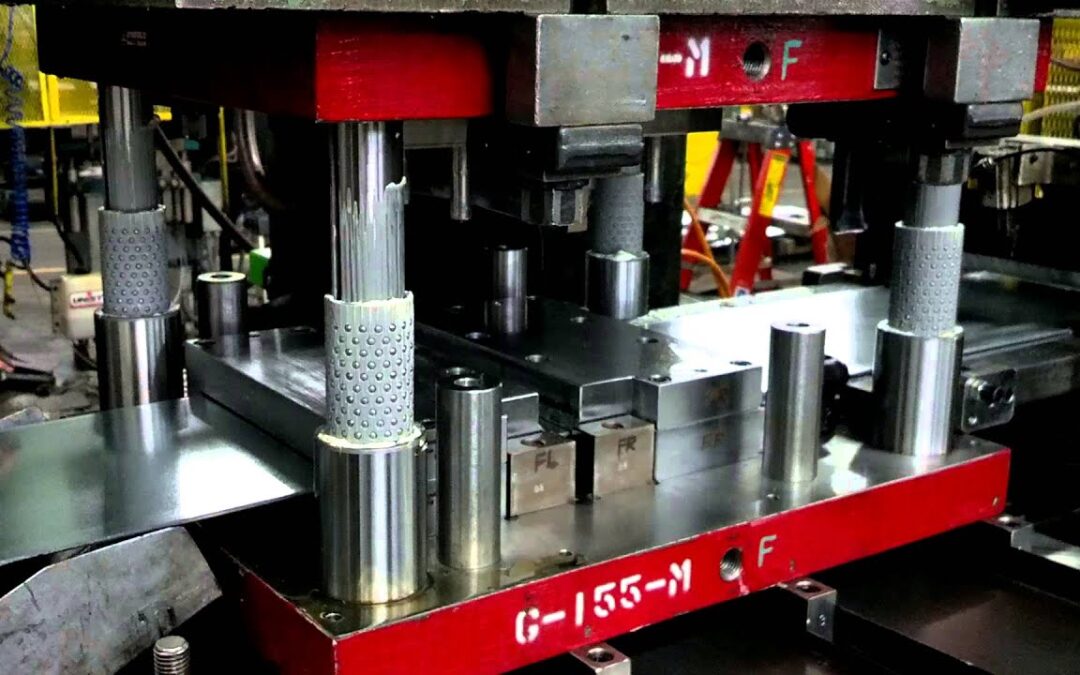

Metal stamping is commonly referred to as sheet metal stamping. It is the process of shaping sheet metal into the shape or pattern of your choice using a stamping press and dies (tooling). The tool and die surface manipulate the metal in a variety of ways until the required shape or form is obtained. Die is a term used to describe the tooling that was used to create a workpiece’s ultimate form. This manufacturing technique can support projects or requirements for the production of medium- to high-volume metal parts at competitive prices.

Metal Stamping As a Profession

Even though metal stamping is a common practice, few individuals appreciate the art of the skill. Metal Sheet work is typically thought of as a filthy factory job. But as the business has developed over time, die designers and producers now rely more on their heads than their hands. For industries to operate in a way that satisfies client expectations, the output must satisfy a particular standard of excellence.

When designing bits and components, they must precisely fit into the corresponding location. Dimensional precision is essential to the position. Metal stamping is a trade that requires science, even though some people view the job as an artistic endeavor. Although the job largely utilizes the scientific mind, it also contains a creative component. To create innovative ways to deliver parts that work properly, toolmakers and designers employ creative thought.

Every day, diemakers and designers make choices that affect their company’s profitability. The company could lose thousands of dollars due to one bad choice. Consequently, even if many people have discounted the professionalism of a career in metal stamping, the work is difficult and demands experience, knowledge, and skill.

Major Types Of Metal Stamping

- Four-Slide Stamping

A method of metalworking called four-slide stamping makes it easier to make intricate pieces. It employs four tools, each of which simultaneously bends the metal into the desired shape. When a project calls for numerous components with various bends, four-slide stamping allows for modifying or adjusting the design. But doesn’t produce pieces with as much regularity as progressive stamping.

- Deep Draw Metal Stamping

A punch is used to feed a blank into a die for deep drawing. It functions best for applications when a customer requires extremely deep part shapes. Typically, the automotive and aerospace industries require parts with sweeping and deep forms. Compared to other stamping techniques, deep drawing requires less raw material. Additionally, it is effective for mass-producing less intricate parts.

- Progressive Die Metal stamping

Strip metal is moved through a progressive stamping press, it is also known as prog die stamping. The metal is formed, punched, bent, and cut at each station according to a specified task. Progressive stamping typically necessitates the use of many stations or stages, particularly when a project calls for complicated pieces. The advantages of progressive stamping include quick turnaround and the production of repeatable, uniform components. Additionally, it has the lowest labor cost among all types of stamping.

Benefits Of Metal Stampings In The Aerospace And Defense Industries

- Strength and Resilience: Metal stampings are remarkably strong and resilient, withstanding corrosion as well as high temperatures, pressures, and forces.

- Customization Possibilities: Metal stampings provide a wide range of customization options, enabling the manufacturing of intricate parts with accurate dimensions and fit.

- Cost-Effectiveness: Metal stampings offer an affordable option for producing intricate parts. The high efficiency of the method lowers manufacturing costs and material prices without sacrificing quality.

- High Level Of Quality Control: Metal stamping complies with industry standards for dependable and high-quality components and guarantees a high level of quality control through precise manufacturing processes and stringent testing methods.

- Material Flexibility: Metal stampings come in a variety of materials, such as copper, titanium, stainless steel, and aluminum. It enables components to survive abrasive environments and adhere to industry standards.

Conclusion

Metal stamping is a crucial step in producing physical goods that fit into our daily lives. There is no way to predict where the craft of metal stamping will go in the years to come. For more information related to metal stamping Visit Here To Related Post.