The global 2D and 3D machine vision systems market size is projected to grow at a CAGR of 12.60% between 2024 and 2032. The market is being driven by the heightening application of these systems in various sectors such as automotive and food and beverage, among others. In today’s competitive manufacturing landscape, companies are constantly seeking ways to improve efficiency, reduce costs, and enhance quality. One technology that is playing a crucial role in achieving these goals is machine vision. Specifically, 2D and 3D machine vision systems are revolutionizing the manufacturing industry by streamlining inspection processes, improving quality control, enhancing production speed, reducing waste, enabling automation and robotics, and ensuring safety. This blog post explores how these systems are enhancing manufacturing efficiency and transforming the way products are made.

Streamlining Inspection Processes

2D and 3D machine vision systems are being used to automate and improve inspection tasks in various industries. These systems use cameras and image processing algorithms to inspect products for defects, ensuring that only high-quality products reach the market. By automating inspection processes, companies can significantly reduce the time and resources required for manual inspections. This not only improves efficiency but also reduces the risk of human error.

For example, in the automotive industry, 2D and 3D machine vision systems are used to inspect components such as engines, chassis, and body panels for defects. These systems can detect even the smallest deviations from specifications, ensuring that defective parts are identified and corrected before they cause problems in the final product. As a result, manufacturers can improve the quality of their products and reduce the likelihood of recalls, saving time and money in the long run.

Improving Quality Control Quality control

Is a critical aspect of manufacturing, and 2D and 3D machine vision systems are helping companies improve their processes. These systems can inspect products at high speeds and with high accuracy, ensuring that only products that meet strict quality standards are released to the market. By implementing these systems, manufacturers can reduce the number of defective products, improve customer satisfaction, and enhance their reputation in the market.

One industry that has benefited greatly from the use of 2D and 3D machine vision systems is the electronics industry. These systems are used to inspect electronic components such as circuit boards and microchips for defects. By detecting defects early in the manufacturing process, companies can reduce the number of faulty products and improve overall product quality.

Enhancing Production Speed

In addition to improving quality control, 2D and 3D machine vision systems are also helping companies enhance their production speed. These systems can inspect products at high speeds, allowing manufacturers to increase their production rates without compromising on quality. By reducing the time required for inspections, companies can reduce production costs and improve overall efficiency.

For example, in the food and beverage industry, 2D and 3D machine vision systems are used to inspect products such as bottles, cans, and packages for defects. By inspecting products at high speeds, manufacturers can ensure that only high-quality products are shipped to customers, reducing the risk of recalls and improving customer satisfaction.

Reducing Waste

Another key benefit of 2D and 3D machine vision systems is their ability to reduce waste in the manufacturing process. These systems can detect defects early in the production process, allowing companies to correct issues before they result in the production of defective products. By reducing the number of defective products, companies can reduce waste and improve overall efficiency.

For example, in the pharmaceutical industry, 2D and 3D machine vision systems are used to inspect tablets and capsules for defects. By detecting defects early in the production process, manufacturers can reduce the number of defective products and improve overall product quality.

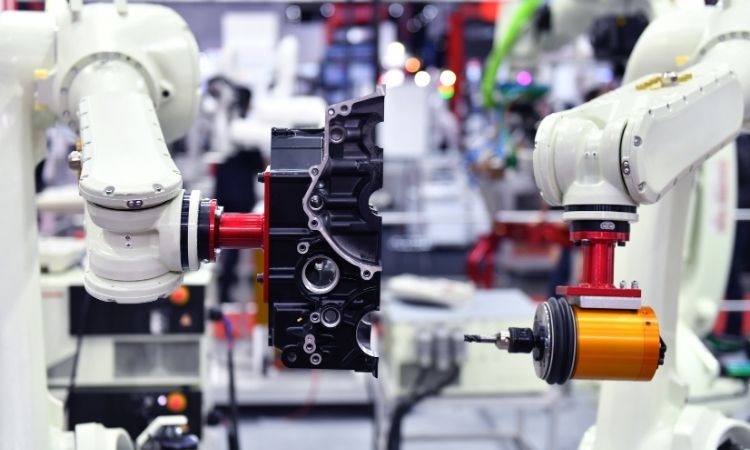

Enabling Automation and Robotics

2D and 3D machine vision systems are also playing a crucial role in enabling automation and robotics in manufacturing. These systems can provide robots with the information they need to perform complex tasks such as picking and placing objects, welding, and assembling products. By enabling automation and robotics, companies can improve efficiency, reduce labor costs, and enhance safety in the manufacturing process.

For example, in the automotive industry, 2D and 3D machine vision systems are used to guide robots in welding and assembling car parts. By providing robots with real-time information about the position and orientation of parts, these systems can improve the accuracy and efficiency of robotic welding and assembly processes.

Ensuring Safety

Finally, 2D and 3D machine vision systems are helping companies ensure the safety of their employees and equipment in the manufacturing process. These systems can detect potential hazards such as moving parts, sharp edges, and hot surfaces, allowing companies to take corrective action to prevent accidents. By ensuring safety in the workplace, companies can reduce the risk of injuries and equipment damage, improving overall efficiency and productivity.

For example, in the aerospace industry, 2D and 3D machine vision systems are used to inspect aircraft components for defects and damage. By detecting potential safety hazards early in the manufacturing process, companies can reduce the risk of accidents and ensure the safety of their employees and equipment.