Sodium silicate, commonly known as water glass, is a versatile compound used in various industries, including construction, detergents, and agriculture. It is produced by the reaction of sodium carbonate with silica at high temperatures. The production process, while beneficial for various applications, raises several environmental concerns that must be addressed to ensure sustainable practices.

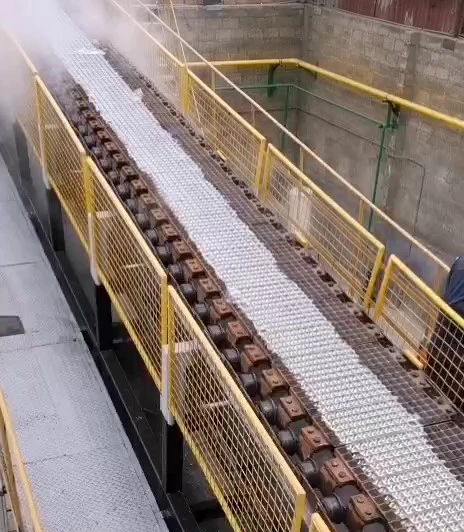

Raw Material Sourcing

The primary raw materials for sodium silicate production line are sodium carbonate and silica. Sodium carbonate is often derived from natural sources, such as trona ore or through the Solvay process. Silica is typically obtained from quartz sand. The extraction and processing of these materials can have significant environmental impacts, including habitat destruction, water usage, and pollution. Sustainable sourcing practices are essential to minimize these effects.

Energy Consumption in Production

The production of sodium silicate requires substantial energy, primarily due to the high temperatures needed for the reaction. This energy consumption contributes to greenhouse gas emissions, especially if fossil fuels are used. Transitioning to renewable energy sources, such as solar or wind power, can help reduce the carbon footprint of sodium silicate production. Energy-efficient technologies should also be implemented to lower overall energy requirements.

Water Usage and Management

Water is a critical component in the production of sodium silicate, both in the chemical processes and for cooling purposes. The extraction of raw materials and the production process can lead to significant water consumption, which may strain local water resources. Implementing water recycling and treatment systems can help mitigate these impacts. Additionally, companies should assess their water usage and strive to minimize waste.

Waste Generation and Disposal

The production of sodium silicate generates various waste products, including dust, sludge, and chemical by-products. Proper waste management practices are essential to prevent pollution and environmental degradation. Recycling and reusing waste materials can reduce the overall waste generated. Furthermore, companies should adhere to regulations regarding waste disposal to ensure that harmful substances do not enter the environment.

Air Emissions and Pollution Control

The production process of sodium silicate can release air pollutants, including particulate matter and volatile organic compounds (VOCs). These emissions can have detrimental effects on air quality and human health. Implementing effective pollution control technologies, such as scrubbers and filters, can significantly reduce air emissions. Regular monitoring of air quality is also necessary to ensure compliance with environmental standards.

Impact on Biodiversity

The extraction of raw materials for sodium silicate production can lead to habitat destruction and loss of biodiversity. Mining activities can disrupt local ecosystems and threaten wildlife. To mitigate these impacts, companies should conduct environmental impact assessments before starting new projects. Additionally, implementing restoration plans for disturbed areas can help preserve biodiversity and promote ecological balance

.

Regulatory Compliance and Standards

Sodium silicate producers must comply with various environmental regulations and standards set by governmental bodies. These regulations are designed to protect the environment and public health. Companies should stay informed about relevant laws and ensure that their operations meet or exceed these requirements. Regular audits and assessments can help identify areas for improvement and ensure compliance.

Sustainable Practices and Innovations

In recent years, there has been a growing emphasis on sustainable practices in sodium silicate production. Innovations such as green chemistry and the use of alternative raw materials can reduce environmental impacts. For example, using bio-based materials instead of traditional raw materials can lower the carbon footprint. Companies should invest in research and development to explore sustainable alternatives and improve production processes.

Community Engagement and Responsibility

Engaging with local communities is crucial for sodium silicate producers. Companies should communicate openly about their operations and the potential environmental impacts. Involving communities in decision-making processes can foster trust and collaboration. Additionally, companies should contribute to local development initiatives and support environmental conservation efforts to demonstrate their commitment to sustainability.

Conclusion

Environmental considerations in sodium silicate production are essential for ensuring sustainable practices. By addressing issues related to raw material sourcing, energy consumption, water usage, waste generation, air emissions, and biodiversity, companies can minimize their environmental impact. Embracing sustainable practices and innovations will not only benefit the environment but also enhance the long-term viability of the sodium silicate industry. It is imperative for producers to prioritize environmental stewardship in their operations.